Electroplating

At SAR Coatings, we specialize in electroplating with an iridescent color, a process that not only protects metals from corrosion but also enhances their lifespan. Our zinc plating services offer more than just protection; they also provide a decorative finish, giving products a bright and shiny appearance that is visually appealing. This decorative finish is not only attractive but also cost-effective compared to other electroplating metals.

We are not just a service provider; we are passionate about the plating process. Our dedication to what we do drives us to continuously improve and innovate, ensuring that we always deliver the best results.

Our unwavering commitment to excellence, especially in the automotive sector, has earned us a reputation as a trusted and reliable partner in the electroplating industry. Whether it’s protecting metal parts from corrosion or providing a decorative finish, you can count on us to deliver superior results every time.

With our expertise and state-of-the-art facilities, we can handle projects of any size and complexity. Our team of skilled professionals is dedicated to meeting the needs of our customers and exceeding their expectations. We understand the importance of quality, reliability, and efficiency in the electroplating process, and we are committed to delivering nothing less than the best. Choose SAR Coatings for all your zinc plating and surface treatment needs, and experience the difference that passion and dedication can make.

PRODUCT BENEFITS

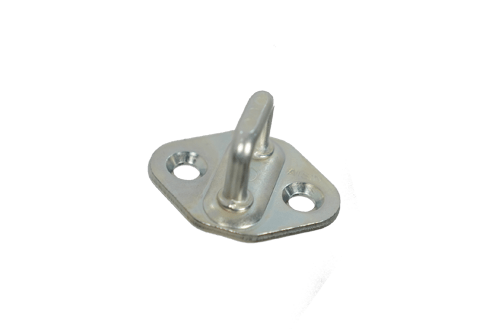

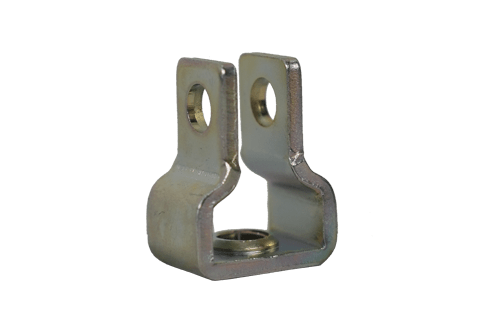

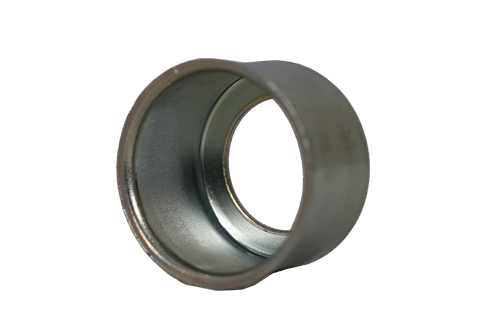

- Ideal for bolts, screws, and other fasteners

- Up to 120 hours of White Rust in SST

- Aesthetically appealing RAINBOW color effect

FAQ's

Zinc plating barrel is a container used in electroplating processes to hold small parts and immerse them in a zinc plating bath. The barrel rotates or tumbles during plating to ensure even coating on all surfaces.

Electroplating is an electrochemical process used to deposit a thin layer of metal onto a conductive surface. It is commonly used to provide corrosion resistance, improve appearance, or enhance conductivity of the plated object.

Small to medium-sized metal parts with complex shapes, such as screws, bolts, nuts, washers, brackets, and other hardware components, can be plated using the barrel method.

In zinc plating, the parts to be plated are first cleaned to remove any dirt, oils, or oxides. They are then immersed in an electrolyte solution containing zinc ions. The solution is subjected to an electric current, which causes the zinc ions to deposit on the components’ surfaces.

Reputable plating service providers like Sarcoatings conduct various quality control tests to ensure the thickness, adhesion, and overall quality of the plated layer. They may provide certificates or reports upon request.