Surface Treatment

PRODUCT BENEFITS

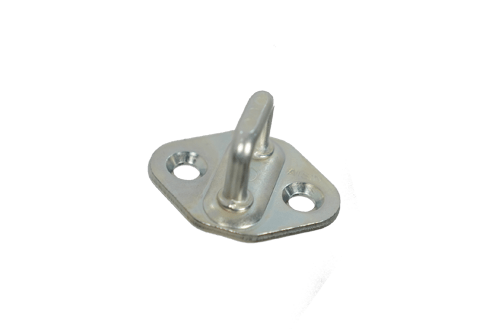

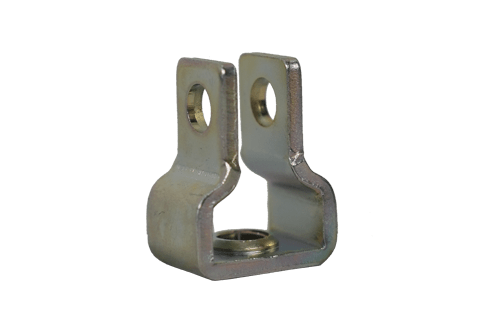

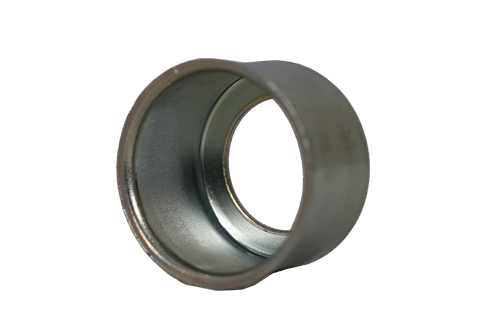

- Ideal for bolts, screws, and other fasteners

- Up to 120 hours of White Rust in SST

- Aesthetically appealing RAINBOW color effect

FAQ's

Zinc plating barrel is a container used in electroplating processes to hold small parts and immerse them in a zinc plating bath. The barrel rotates or tumbles during plating to ensure even coating on all surfaces.

Electroplating is an electrochemical process used to deposit a thin layer of metal onto a conductive surface. It is commonly used to provide corrosion resistance, improve appearance, or enhance conductivity of the plated object.

Small to medium-sized metal parts with complex shapes, such as screws, bolts, nuts, washers, brackets, and other hardware components, can be plated using the barrel method.

In zinc plating, the parts to be plated are first cleaned to remove any dirt, oils, or oxides. They are then immersed in an electrolyte solution containing zinc ions. The solution is subjected to an electric current, which causes the zinc ions to deposit on the components’ surfaces.

Reputable plating service providers like Sarcoatings conduct various quality control tests to ensure the thickness, adhesion, and overall quality of the plated layer. They may provide certificates or reports upon request.